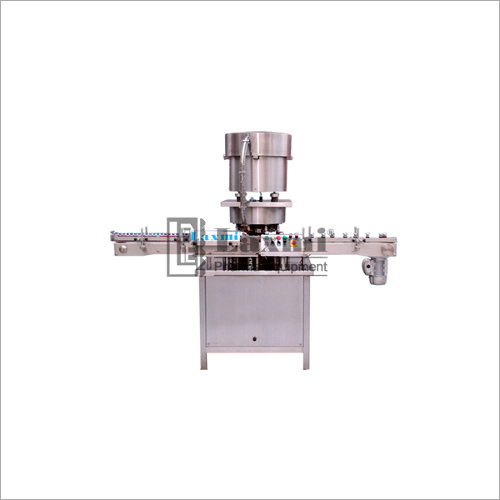

Automatic Eight Head Aluminum Cap Sealing Machine

Price 250000 - 120000000 INR/ Piece

Automatic Eight Head Aluminum Cap Sealing Machine Specification

- Phase

- Single / Three Phase

- Features

- High Speed, Accurate Sealing, Low Maintenance, User Friendly Interface

- Temperature

- Room Temperature Operation

- Noise Level

- < 80 dB

- Usage & Applications

- Pharmaceutical, Beverage, Cosmetic, Chemical Bottle Sealing

- Frequency

- 50 Hz / 60 Hz

- Type

- Automatic Eight Head Aluminum Cap Sealing Machine

- Material

- Stainless Steel & Aluminum

- Capacity

- Up to 120 bottles/min

- Computerized

- Yes

- Control Mode

- PLC Controlled

- Voltage

- 220V / 380V

- Power

- 3 kW

- Weight (kg)

- Approx. 650 kg

- Dimension (L*W*H)

- 2000 mm x 900 mm x 1700 mm

- Color

- Silver

- Body Finish

- Matt & Mirror Polished

- Integration

- Compatible with Filling Line & Labeling Machine

- Sealing Heads

- 8 Automatic Heads

- Display

- Digital HMI Touch Screen

- Safety

- Overload Protection & Emergency Stop

- Changeover Time

- Quick & Tool-less

- Conveyor Length

- Customized (Standard 6 feet)

- Environment

- Dust Proof Enclosure

- Bottle Diameter Range

- 20 mm to 100 mm

- Cap Diameter Range

- 18 mm to 38 mm

- Air Pressure Required

- 6 kg/cm²

- Bottle Height Range

- 50 mm to 250 mm

- Operation

- Continuous In-Line

- Lubrication System

- Automatic

Automatic Eight Head Aluminum Cap Sealing Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 3500000 Pieces Per Day

- Delivery Time

- 45 Days

About Automatic Eight Head Aluminum Cap Sealing Machine

Our company is eagerly indulged in manufacturing and supplying a world-class Automatic Eight Head Aluminum Cap Sealing Machine. It has great usage in industry of pharmaceuticals, cosmetic, chemicals, pesticide, food & beverages, etc. Powered by single motor synchronizes conveyor, platform turret, star wheels, and featured with spring loaded free spinning rollers, all the liquid contact parts are well designed and fabricated from SS316 grade stainless steel, and body structure made from SS304 pipe. Automatic Eight Head Aluminum Cap Sealing Machine comes in varied models, capacities and specifications.

Specifications:

| Model No | LACS 150 |

| Filling Heads | 8 Heads |

| Output/ Min | 150 VPM |

| Power Characteristics | 440 v 3 Phase 50 Hz 4 Wire System |

| Cap Size | 13 mm/ 20 mm (Plan & Flip Off) |

| Filling Accuracy | ±1 % |

| Net Weight | 650 kgs |

| Machine Length | 1800 mm |

| Machine width | 1050 mm |

| Machine height | 1350 mm |

High-Speed Accuracy for Diverse Industries

Designed for maximum output, the Automatic Eight Head Aluminum Cap Sealing Machine boasts up to 120 bottles per minute capacity, making it ideal for large-scale operations in pharmaceuticals, beverages, cosmetics, and chemicals. Its high-precision sealing heads rotate continuously in-line, guaranteeing consistent and secure seals for each bottle, while its compatibility with various bottle and cap sizes provides flexibility for an array of applications.

Advanced Control and Safety Features

Enjoy streamlined operation with PLC controls and a digital HMI touch interface for user-friendly, intuitive monitoring. Enhanced with overload protection and emergency stop controls, the machine prioritizes operator safety during high-speed production. The automatic lubrication system and dust-proof enclosure further enhance durability and low-maintenance performance, ensuring operational excellence and minimal downtime.

Easy Integration and Versatility

Built with integration in mind, this sealing machine seamlessly connects with most filling and labeling systems, supporting continuous production lines. The adjustable conveyor (customizable length) and tool-less, quick changeover allow rapid adaptation to different bottles and caps, making it an adaptable choice for businesses seeking to expand or diversify their product offerings.

FAQ's of Automatic Eight Head Aluminum Cap Sealing Machine:

Q: How does the Automatic Eight Head Aluminum Cap Sealing Machine improve production efficiency?

A: The machine features a continuous in-line operation with eight automatic sealing heads, allowing up to 120 bottles per minute. Its PLC-controlled system, quick and tool-less changeover capabilities, and automatic lubrication minimize downtime and maintenance, significantly boosting overall production speed and consistency.Q: What types and sizes of bottles and caps can this machine handle?

A: This machine accommodates bottles with diameters ranging from 20 mm to 100 mm and heights from 50 mm to 250 mm. It seals aluminum caps between 18 mm to 38 mm in diameter, making it suitable for various products in the pharmaceutical, beverage, cosmetic, and chemical industries.Q: When is a changeover required, and how is it performed?

A: A changeover is required when switching to different bottle or cap sizes. The machine is designed for rapid, tool-less changeovers, enabling operators to adjust quickly and efficiently without special equipment, reducing downtime and maintaining productivity.Q: Where can this sealing machine be integrated within a production line?

A: The machine is compatible with existing filling and labeling lines, allowing seamless integration for an automated, continuous workflow. Its conveyor length can be customized to suit specific line requirements, making it adaptable for various facility layouts.Q: What is the process of operating this machine?

A: Operation involves setting up bottles and caps on the conveyor, configuring parameters via the digital HMI touch screen, and initiating the automated sealing cycle. The PLC controls manage the entire process, while built-in safety and overload features protect operators and ensure reliability.Q: What are the main benefits of using this sealing machine?

A: Key benefits include high sealing accuracy, fast production rates, simple operation with digital controls, low maintenance due to automated lubrication, safety features, dust-proof enclosure, and the ability to handle a wide range of bottle and cap sizes, supporting business growth and versatility.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cap Sealing Machine Category

Semi Automatic Aluminum Cap Sealing Machine

Price 250000 - 120000000 INR / Piece

Minimum Order Quantity : 1 Piece

Voltage : 220 V

Dimension (L*W*H) : 650 mm x 500 mm x 1050 mm

Computerized : No

Capacity : 500 1200 bottles per hour

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free