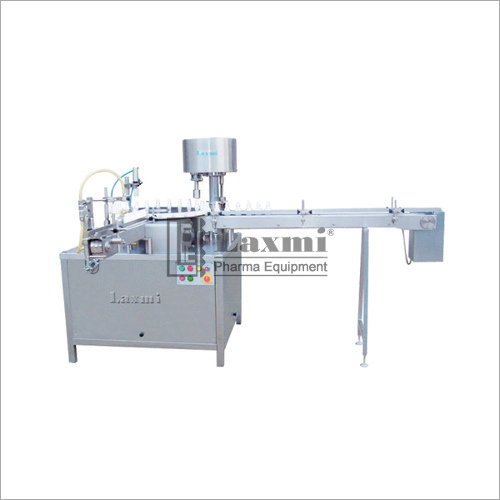

Automatic High Speed Six Head Bottle Filling Machine

Price 250000 - 120000000 INR/ Piece

Automatic High Speed Six Head Bottle Filling Machine Specification

- Product Type

- Automatic High Speed Six Head Bottle Filling Machine

- Material

- Stainless Steel (SS 304/316 contact parts)

- Application

- Liquid Filling for Pharmaceutical, Food, Beverage, Chemical Industries

- Packaging Material

- Bottles (PET, Glass, HDPE, etc.)

- Computerized

- Yes

- Automatic Grade

- Automatic

- Control System

- PLC Based Control System

- Drive Type

- Electric Motor Driven

- Voltage

- 220-240V (Single Phase) / 415V (Three Phase)

- Weight (kg)

- Approx. 700-850 kg

- Dimension (L*W*H)

- 2200mm x 900mm x 1750mm

- Capacity

- 3000-5000 Bottles Per Hour (Depending on bottle size)

- Feature

- High speed, Accurate filling, Minimal wastage

- Color

- Silver

- Number of Heads

- 6

- Filling Range

- 30 ml to 1000 ml

- Filling Accuracy

- 1%

- Change Parts Required

- Minimal for bottles of similar neck diameter

- Cleaning

- Easy-to-clean, Tool-less changeover

- Bottle Diameter Supported

- 30100 mm

- Power Consumption

- 2.5 kW

- Compressed Air Required

- 6 Bar (if required for application)

- Safety Features

- Emergency Stop, Overload Protection, Interlocked Guards

- Operator Panel

- Color Touchscreen

- Integration Capability

- Compatible with Capping, Labeling & Packing Lines

- Filling Principle

- Volumetric / Piston based

- Suitable For

- Low and High Viscosity Liquids

- Speed Variation

- Variable Speed via Inverter Drive

- Conveyor Length

- 8 feet (customizable)

Automatic High Speed Six Head Bottle Filling Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 3500000 Pieces Per Day

- Delivery Time

- 45 Days

About Automatic High Speed Six Head Bottle Filling Machine

Automatic High Speed Six Head Bottle Filling Machine, driven by three phase electric power, is designed for filling plastic/glass bottle with liquid at speed from 60 to 250 bottles/min. The body structure as well as contact/non-contact parts are well designed and fabricated from stainless steel of the best grade with the help of advanced technology in accordance with international standard. It has user-friendly operating unit and ergonomic design that enable operator to operate the machine easily. Besides, Clients can buy Automatic High Speed Six Head Bottle Filling Machine at compromising prices.

Product Details:

| Material | SS |

| Brand | Laxmi Pharma Equipment |

| Machine Capacity | 60-240 bottles/min |

| Voltage | 415 V 50 Hz |

| Packaging Type | Bottles |

| Filling Speed | 60-250 BPM |

| Orientation | Horizontal |

| Automatic Grade | Automatic |

| Phase | Three Phase |

| Usage/Application | Industrial |

| Driven Type | Electric |

| Machine Type | Automatic |

Technical Specifications:

| Model No | ALFT 151 |

| Filling Heads | 6 Heads |

| Output/ Min | 150 BPM |

| Power Characteristics | 440v 3 Phase 50Hz 4 Wire System |

| Input (Container Dia/ Height) | 40mm Dia to 100mm Dia/ Height 100mm Max. |

| Fill Volume | 30 ml to 500ml |

| Filling Accuracy | 1 % |

| Net Weight | 600 kgs |

| Machine Length | 4400mm |

| Machine width | 800mm/ 1600mm (Apro) |

| Machine height | 1700mm |

Engineered for Speed & Accuracy

This six-head filling machine combines robust construction and cutting-edge volumetric filling technology to deliver high-speed operation with remarkable precision. Adjustable inverter-driven speed allows seamless adaptation to various production demands, ensuring minimal product wastage and consistent results for each bottle filled, regardless of shape or viscosity.

Versatile Liquid Handling & Integration

Suitable for a wide array of fluids, from thin solutions to viscous liquids, the machine excels in versatility. Seamlessly integrate it with downstream capping, labeling, and packing lines to create a fully automatic bottling system. Its user-friendly color touchscreen panel and PLC control further elevate operational efficiency and flexibility.

Enhanced Safety & User Experience

Multiple safety features, including emergency stop, interlocked guards, and overload protection ensure the safety of operators and equipment. The ergonomic design, easy-to-clean surfaces, tool-less changeover, and minimal change parts make routine operation and maintenance straightforward, reducing downtime and enhancing productivity.

FAQs of Automatic High Speed Six Head Bottle Filling Machine:

Q: How does the six-head bottle filling machine ensure high filling accuracy?

A: The machine uses a volumetric or piston-based filling principle, which provides precise control over liquid volume dispensed into each bottle. This approach achieves an exceptional filling accuracy of 1%, minimizing product wastage and ensuring uniformity.Q: What is the process for changing between different bottle sizes or products?

A: Changeovers are streamlined thanks to minimal change parts, particularly when bottle neck diameters are similar. The tool-less design and color touchscreen panel enable users to swiftly adjust settings and parameters for different bottle sizes and liquid types, minimizing downtime.Q: When should compressed air be provided for the machine, and is it always necessary?

A: Compressed air at 6 bar is required only for specific applications, such as handling viscous liquids or certain types of valve operations. For standard use, the electric motor drive is sufficient unless your specific product or process demands air-supported mechanisms.Q: Where can this filling machine be integrated within a production line?

A: The machine is engineered for compatibility with other bottling line equipment including capping, labeling, and packaging machines. It easily becomes part of a larger fully automated bottling process, enhancing overall production efficiency in your facility.Q: How does the machine handle different liquid viscosities?

A: Designed for optimal versatility, the six-head filling machine efficiently processes both low and high viscosity liquids. The robust piston mechanism and speed variation capability ensure smooth and accurate filling, regardless of the liquids thickness.Q: What are the main benefits of using this automatic high speed filling machine?

A: The major benefits include high throughput (up to 5000 bottles per hour), superior filling accuracy, reduced wastage, fast and easy cleaning, minimal changeover time, enhanced safety systems, and reliable, computerized PLC-based operation, all contributing to improved productivity and cost savings.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Liquid Filling Machine Category

Portable Liquid Filling Machine

Price 110000 INR / Piece

Minimum Order Quantity : 1 Piece

Control System : Frequency Speed Control

Drive Type : Manual

Product Type : Pharmaceutical Packaging

Packaging Material : Wood

Automatic Oral Liquid Bottle Filling Machine

Price 250000 - 1500000 INR / Piece

Minimum Order Quantity : 1 Piece

Control System : PLC Control

Drive Type : Electric

Product Type : Pharmaceutical Packaging

Packaging Material : Plastic

Eye Drop bottle Filling and Sealing Machine

Price 375000 INR / Piece

Minimum Order Quantity : 1 Number

Control System : Frequency Speed Control

Drive Type : Electric

Product Type : Pharmaceutical Packaging

Packaging Material : Wood

Automatic High Speed Eight Head Bottle Filling Machine

Price 250000 - 120000000 INR / Piece

Minimum Order Quantity : 1 Piece

Control System : Other, PLC Based

Drive Type : Electric

Product Type : Automatic High Speed Eight Head Bottle Filling Machine

Packaging Material : Other, Bottles (PET, Glass, HDPE)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS