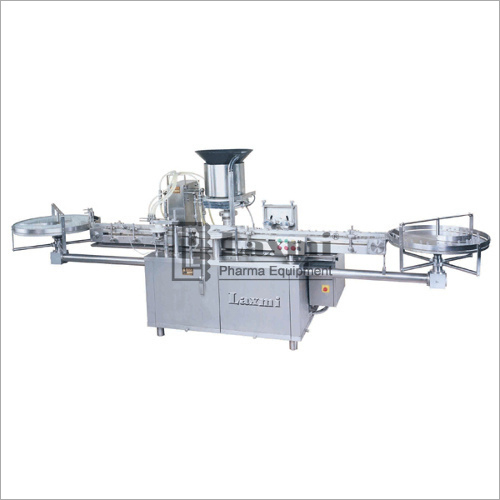

Pharmaceutical Liquid Filling Line

Price 250000 - 120000000 INR/ Piece

Pharmaceutical Liquid Filling Line Specification

- Usage & Applications

- Pharmaceutical Bottle Liquid Filling, Syrups, Oral Solutions

- Features

- High Precision Filling, No-Drip, No Bottle-No Fill, Easy Changeover, Built-in Safety Features

- Phase

- Three Phase

- Noise Level

- <75 dB

- Frequency

- 50/60 Hz

- Temperature

- 5-45C (Operating)

- Type

- Automatic Pharmaceutical Liquid Filling Line

- Material

- Stainless Steel (SS 304/316)

- Capacity

- 60-240 Bottles per Minute (Adjustable)

- Computerized

- Yes

- Control Mode

- PLC Control with Touchscreen HMI

- Voltage

- 220-440V

- Power

- 2-4 kW

- Weight (kg)

- Approx. 1200 kg

- Dimension (L*W*H)

- 3000 mm x 1000 mm x 1700 mm

- Color

- Silver (Stainless Steel Finish)

- Bottle Diameter

- 22 mm to 100 mm

- Filling Range

- 10 ml to 500 ml (Customizable)

- Number of Filling Heads

- 4/6/8/12 Heads (As per model)

- Filling Accuracy

- ±1%

- Cleaning System

- CIP (Clean-In-Place) Compatible

- Lubrication

- Centralized Automatic Lubrication

- Compressed Air Requirement

- 6 Bar

- Bottle Labeling

- Inline Labeling System (Optional)

- Filling Principle

- Volumetric / Peristaltic Pump (Based on requirement)

- Capping System

- Integrated Automatic Capping Unit

- Bottle Material Compatibility

- PET, Glass, HDPE, PP

- Conveyor Type

- Slat Conveyor with Adjustable Speed

- Safety Features

- Emergency Stop, Interlocked Guards, Overload Protection

Pharmaceutical Liquid Filling Line Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 3500000 Pieces Per Day

- Delivery Time

- 45 Days

About Pharmaceutical Liquid Filling Line

High Precision and Versatility

Engineered for accuracy, the filling line achieves 1% precision through advanced volumetric or peristaltic pumps. Its customizable filling head options allow adaptation to varying production requirements. Whether filling small oral solution bottles or larger syrup containers, the versatile design supports a wide array of pharmaceutical products.

Robust Construction & Safety Features

Manufactured from stainless steel (SS 304/316), the line ensures long-lasting performance and hygiene compliance. Integrated safety measures such as emergency stop, interlocked guards, and overload protection safeguard both operators and your investment, making it suitable for regulatory environments.

Automated Operations & Easy Integration

With a PLC-based control system, touchscreen HMI, centralized lubrication, and automatic capping and labeling, this system streamlines production and simplifies operator training. The slat conveyor's speed is adjustable for optimal flow, while optional inline labeling provides comprehensive packaging solutions.

FAQ's of Pharmaceutical Liquid Filling Line:

Q: How does the liquid filling line ensure filling accuracy and minimize product waste?

A: The system utilizes volumetric or peristaltic pumps, achieving a filling accuracy of 1%. Features like no-drip nozzles and a 'No Bottle-No Fill' function reduce spillage and minimize product waste, ensuring consistent and efficient operation.Q: What types of bottles and materials are compatible with this filling line?

A: The filling line accommodates bottles with diameters ranging from 22 mm to 100 mm, made of PET, glass, HDPE, or PP. This flexibility supports a wide spectrum of pharmaceutical bottle types and sizes.Q: When should Clean-In-Place (CIP) cleaning be performed on the filling line?

A: CIP cleaning should be conducted according to your facility's hygiene standards, typically at the end of each production lot or shift. The CIP compatibility of the line facilitates efficient internal cleaning with minimal downtime.Q: What is the process for changing bottle sizes or filling volumes on this equipment?

A: Changeover is designed to be quick and straightforward. Adjustments for bottle diameter, filling volume (10 ml to 500 ml), and speed can be made via the touchscreen HMI, minimizing downtime and ensuring flexible production.Q: Where is this pharmaceutical liquid filling line typically used?

A: It is widely deployed in pharmaceutical manufacturing facilities across India and internationally, handling products such as liquid syrups and oral solutions. Its design meets strict industry requirements for hygiene, accuracy, and productivity.Q: How does the integrated safety system protect operators and machinery?

A: The filling line is equipped with emergency stops, interlocked safety guards, and overload protection, effectively preventing accidents and equipment damage during operation.Q: What are the main benefits of using this automatic filling line?

A: Users benefit from high throughput, precise and hygienic filling, automated capping and labeling, intuitive PLC controls, easy maintenance, and built-in safety, making it ideal for modern pharmaceutical production environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Vial Filling Machine Category

Vial Filling And Stoppering Machine

Price 250000 INR / Piece

Minimum Order Quantity : 15 Pieces

Voltage : 220240V

Material : Stainless Steel (SS 304/316)

Computerized : Yes

Control Mode : Other, PLC Controlled

Automatic Eight Head Vial Filling Machine

Price 250000 - 120000000 INR / Piece

Minimum Order Quantity : 1 Piece

Voltage : 220 V / 50 Hz

Material : Stainless Steel

Computerized : Yes

Control Mode : Other, PLC Controlled

Automatic Four Head Vial Filling And Stoppering Machine

Price 250000 INR / Piece

Minimum Order Quantity : 15 Pieces

Voltage : 220V / 380V (as per requirement)

Material : Stainless Steel (SS 316/304 contact parts)

Computerized : Yes

Control Mode : Other, PLC Based with HMI Touch Screen

Automatic Vial Filling Machines

Price 250000 - 120000000 INR / Piece

Minimum Order Quantity : 1 Piece

Voltage : 220240 V

Material : Stainless Steel

Computerized : Yes

Control Mode : Other, PLC

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free