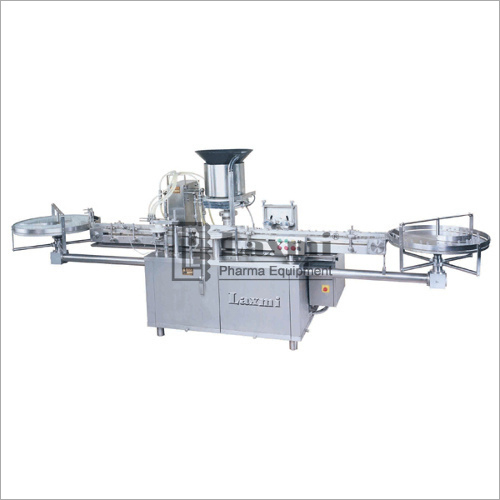

Automatic Four Head Vial Filling And Stoppering Machine

Price 250000 INR/ Piece

Automatic Four Head Vial Filling And Stoppering Machine Specification

- Temperature

- Ambient working temperature

- Frequency

- 50 Hz / 60 Hz

- Features

- Automated operation, accurate filling, no vial-no fill system, inbuilt safety features, GMP compliant

- Usage & Applications

- Pharmaceutical vial filling and bunging/stoppering

- Phase

- Three Phase

- Noise Level

- Less than 70 dB

- Type

- Automatic Four Head Vial Filling And Stoppering Machine

- Material

- Stainless Steel (SS 316/304 contact parts)

- Capacity

- Up to 120 vials per minute (depending on vial size and fill volume)

- Computerized

- Yes

- Control Mode

- PLC Based with HMI Touch Screen

- Voltage

- 220V / 380V (as per requirement)

- Power

- 2 kW

- Weight (kg)

- Approx. 600 kg

- Dimension (L*W*H)

- 2500 mm x 1000 mm x 1800 mm

- Color

- SS Finish

- Finish

- Matt/Glossy as per GMP standard

- Drive Mechanism

- Servo/Stepper Motor Driven

- Bottle Guides

- Adjustable SS guides for various vial sizes

- Number of Filling Heads

- 4

- Cleaning

- CIP (Clean In Place) & SIP (Sterilize In Place) compatible

- Changeover Time

- Quick and tool-less changeover

- Filling Accuracy

- ±1% depending on liquid and volume

- Conveyor Width

- 100 mm

- Documentation

- IQ/OQ/DQ and FAT documentation as per pharmaceutical standards

- Compressed Air Requirement

- 6 Bar, 0.5 CFM

- Number of Stoppering Heads

- 1 Vibratory bowl for rubber stoppers

- Filling System

- Syringe/Bosch type Ceramic piston

- Output Counter

- Digital batch counter available

- Safety Interlocks

- Provided for Door open, Overload, and Emergency stop

- Suitable Vial Range

- 2 ml to 100 ml

Automatic Four Head Vial Filling And Stoppering Machine Trade Information

- Minimum Order Quantity

- 15 Pieces

- Supply Ability

- 3500000 Pieces Per Day

- Delivery Time

- 45 Days

About Automatic Four Head Vial Filling And Stoppering Machine

Used By, Features & Machine Highlights

The Automatic Four Head Vial Filling and Stoppering Machine is widely used by pharmaceutical exporters, manufacturers, wholesalers, and suppliers to streamline vial filling and stoppering operations. Key features include up to 120 vials per minute capacity, 1% filling accuracy, and PLC-based HMI for smooth control. The machine is equipped with no vial-no fill technology, CIP/SIP compatibility, and GMP-grade stainless steel construction. Its rapid, tool-less changeover further optimizes workflow, establishing industry-leading performance.

Packaging, Certifications & Export Market Value

This imposing system is securely dispatched with meticulous packaging, ensuring safe transit and preservation of its unmatchable quality. The outlay includes IQ/OQ/DQ and FAT documentation, reflecting rigorous adherence to international pharmaceutical standards. Our machine holds high market value across major export destinations in India, Asia, Africa, and beyond. Certified for GMP compliance, it meets the demands of top-tier laboratories and production facilities, consolidating its reputation as a global leader in pharmaceutical machinery.

FAQ's of Automatic Four Head Vial Filling And Stoppering Machine:

Q: How does the Automatic Four Head Vial Filling and Stoppering Machine ensure filling accuracy?

A: The machine utilizes advanced syringe/Bosch type ceramic piston technology, paired with servo/stepper motor drives, to achieve a filling accuracy of 1%, depending on the liquid and volume.Q: What are the main benefits of using this vial filling and stoppering system?

A: Primary benefits include rapid and tool-less changeover, precise automated operation, comprehensive safety interlocks, consistent output up to 120 vials per minute, and full compliance with GMP and pharmaceutical documentation standards.Q: Which industries commonly use this machine and for what applications?

A: Pharmaceutical manufacturers, exporters, and suppliers commonly use this system for precise vial filling and bunging/stoppering of injectable medications ranging from 2 ml to 100 ml.Q: How is cleaning and sterilization managed for this equipment?

A: The system is CIP (Clean-In-Place) and SIP (Sterilize-In-Place) compatible, allowing thorough internal cleaning and sterilization without dismantling components, saving valuable operational time.Q: Where is the machine exported and what documentation accompanies it?

A: The machine is exported globally, including to markets in India, Asia, and Africa. Each unit is shipped with complete IQ/OQ/DQ and FAT documentation to meet international pharmaceutical compliance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Vial Filling Machine Category

Vial Filling and Rubber Stoppering Machine

Price 250000 INR / Piece

Minimum Order Quantity : 15 Pieces

Control Mode : Other, PLC Controlled with Touchscreen HMI

Computerized : Yes

Voltage : 220V/380V, 50/60Hz

Material : Stainless Steel (SS 316 contact parts)

Automatic Six Head Vial Filling Line

Price 250000 - 120000000 INR / Piece

Minimum Order Quantity : 1 Piece

Control Mode : Other, PLC Controlled

Computerized : Yes

Voltage : 220V/380V AC, 50/60 Hz

Material : Stainless Steel (SS 304/316)

Vial Filling Stoppering And Capping Machine

Price 250000 - 120000000 INR / Piece

Minimum Order Quantity : 1 Piece

Control Mode : Other, PLC Controlled

Computerized : Yes

Voltage : 230V AC

Material : SS 316 / SS 304 Stainless Steel

Automatic Eight Head Vial Filling And Rubber Stoppering Machine

Price 250000 - 120000000 INR / Piece

Minimum Order Quantity : 1 Piece

Control Mode : Other, PLC Controlled

Computerized : Yes

Voltage : 220V/380V, 50Hz

Material : Stainless Steel (SS 304/316)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free