Syrup Filling Machine

Price 250000 - 120000000 INR/ Piece

Syrup Filling Machine Specification

- Product Type

- Syrup Filling Machine

- Material

- Stainless Steel (SS 304/316 contact parts)

- Application

- Pharmaceutical, Food, Beverage industries

- Packaging Material

- Bottles (Glass/Plastic)

- Computerized

- Yes

- Automatic Grade

- Automatic

- Control System

- PLC based

- Drive Type

- Electric

- Voltage

- 220-240V

- Weight (kg)

- Approx 350 kg

- Dimension (L*W*H)

- 2000mm x 900mm x 1500mm

- Capacity

- 20-60 bottles/min (variable)

- Feature

- High accuracy, Easy operation, Drip-free filling, Adjustable speed

- Color

- Silver

- Operation

- Touch screen HMI

- Noise Level

- Less than 70 dB(A)

- Cleaning

- CIP/SIP compatible

- Bottle Diameter Range

- 30mm to 100mm

- Conveyor Length

- 1500mm

- Filling Accuracy

- ±1%

- Filling Range

- 30ml to 500ml

- Power Consumption

- 2 kW

- Number of Filling Heads

- 2, 4, 6, or 8 as required

- Nozzle Type

- Anti-drip diving nozzle

- Air Compressor Requirement

- Not required (fully electric)

Syrup Filling Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 3500000 Pieces Per Day

- Delivery Time

- 45 Days

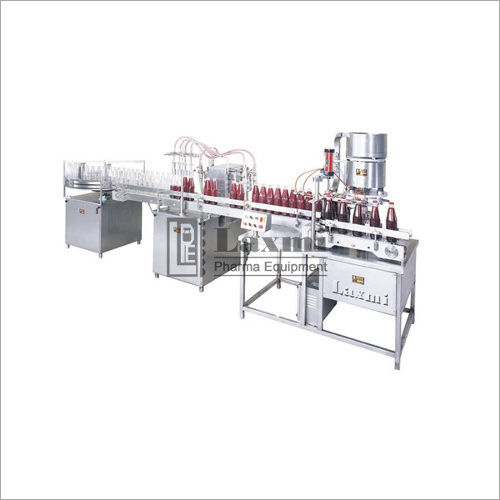

About Syrup Filling Machine

Syrup Filling Machine we propose is a volumetric liquid filling system utilized in pharmaceutical industry for filling 30ml to 500ml volume of liquid into the bottles at speed of 150 BPM. There is an elegant and easy to reach control panel for complete control on operation. Featured with nozzle driving unit, it is made from stainless steel body structure to guarantee its vibration free and trouble free performance. Comes in automatic and manual type, Syrup Filling Machine is effortless to install, durable and can be availed by patrons in varied models at negotiable prices.

Technical Specifications:

| | |

|---|---|

| Model No | ALFT 151 |

| Filling Heads | 6 Heads |

| Output/ Min | 150 BPM |

| Power Characteristics | 440v 3 Phase 50Hz 4 Wire System |

| Input (Container Dia/ Height) | 40mm Dia to 100mm Dia/ Height 100mm Max. |

| Fill Volume | 30 ml to 500ml |

| Filling Accuracy | ±1 % |

| Net Weight | 600 kgs |

| Machine Length | 4400mm |

| Machine width | 800mm/ 1600mm (Apro) |

| Machine height | 1700mm |

High-Precision and Versatile Filling

Engineered for accuracy and efficiency, the machine fills syrup volumes from 30ml to 500ml and can process up to 60 bottles per minute, making it suitable for diverse production scales. The adjustable filling heads provide flexibility for different batch sizes and bottle types, ensuring reliable performance in pharmaceutical, food, and beverage sectors.

User-Friendly Operation and Maintenance

Featuring a touch screen HMI and PLC-based controls, the machine streamlines the filling process for operators. Maintenance is simplified by CIP/SIP compatibility, permitting automated and thorough cleaning. The anti-drip diving nozzle guarantees spill-free transfer, which protects workspaces and improves product yield.

Energy-Efficient and Hygienic Design

This fully electric filling system operates without compressed air, helping minimize energy consumption (2 kW) and keep noise levels low. Stainless steel contact parts ensure robust corrosion resistance, hygiene, and compliance with industry standards for pharmaceuticals and food processing. The adjustable conveyor suits various bottle sizes for operational flexibility.

FAQ's of Syrup Filling Machine:

Q: How does the Syrup Filling Machine achieve high filling accuracy?

A: The machine utilizes an advanced PLC control system combined with anti-drip diving nozzles, which ensures filling accuracy within 1%. This technology minimizes variations in dispensed amounts and prevents product loss due to dripping is enhanced by servo-driven filling mechanisms.Q: What types of bottles and products can be processed with this filling machine?

A: It accepts glass or plastic bottles with diameters ranging from 30mm to 100mm. The filling range of 30ml to 500ml makes it suitable for syrups, liquid pharmaceuticals, food products like sauces, and beverages. Only bottles are required as packaging material, ensuring flexibility across industries.Q: When is cleaning and maintenance needed, and how is it performed?

A: Cleaning should be performed during product changeover, regular maintenance schedules, and after extended operation runs. Thanks to CIP/SIP compatibility, cleaning is automated; users initiate the process via the touchscreen HMI, which circulates cleaning agents and steam through all relevant parts for thorough sterilization.Q: Where can this machine be installed, and is it suitable for industrial environments?

A: This machine is designed for industrial usage and can be installed in pharmaceutical processing plants, food factories, and beverage production lines. Its compact 2000mm x 900mm x 1500mm size and low noise level (<70 dB(A)) make it suitable for both large and medium-sized facilities.Q: What is the process for switching between different bottle sizes or fill volumes?

A: Operators can adjust fill volumes and select bottle sizes through the intuitive touch screen HMI. The conveyor and nozzle positions can be adapted for bottles with diameters between 30mm and 100mm, ensuring rapid and easy changeover between product batches or packaging formats.Q: How does the electric drive system benefit operation and maintenance?

A: The fully electric operation (power consumption: 2 kW, voltage: 220-240V) eliminates the need for an air compressor, simplifying installation and reducing maintenance requirements. It also contributes to lower operating costs and touts a quieter, more reliable filling process.Q: What are the main advantages of choosing this syrup filling machine for production?

A: Key benefits include high filling accuracy, adjustable speed, easy operation via computerized controls, drip-free transfer, robust stainless steel construction, and compatibility with both glass and plastic bottles. Additionally, the machine allows for automated cleaning and meets strict hygiene standards, supporting scalable production for exporters, manufacturers, suppliers, and wholesalers in India.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Liquid Filling Machine Category

Portable Liquid Filling Machine

Price 110000 INR / Piece

Minimum Order Quantity : 1 Piece

Packaging Material : Wood

Computerized : No

Material : SS / MS

Feature : Lower Energy Consumption, ECO Friendly, Simple Control, Low Noise, High Efficiency, Stable Performance

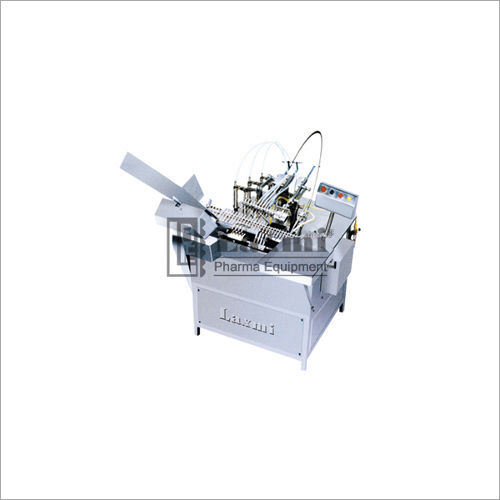

Automatic Ampoule Filling and Sealing Machine

Price 400000 INR / Piece

Minimum Order Quantity : 1 Number

Packaging Material : Wood

Computerized : Yes

Material : SS / MS

Feature : Simple Control, Stable Performance

Automatic High Speed Six Head Bottle Filling Machine

Price 250000 - 120000000 INR / Piece

Minimum Order Quantity : 1 Piece

Packaging Material : Other, Bottles (PET, Glass, HDPE, etc.)

Computerized : Yes

Material : Stainless Steel (SS 304/316 contact parts)

Feature : Other, High speed, Accurate filling, Minimal wastage

Automatic Four Head Liquid Filling Machine

Price 250000 - 120000000 INR / Piece

Minimum Order Quantity : 1 Piece

Packaging Material : Other, Pet, Glass, Plastic Bottles

Computerized : Yes

Material : Stainless Steel 304/316 Contact Parts

Feature : Other, Drip Proof Nozzles, No BottleNo Fill System, Toolless adjustment

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS