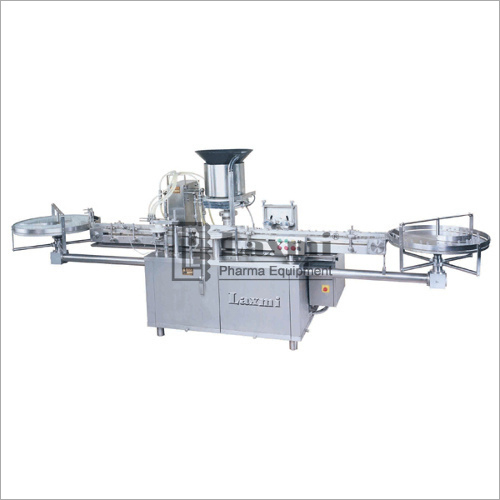

Automatic High Speed Vial Filling and Stoppering Machine

Price 250000 INR/ Piece

Automatic High Speed Vial Filling and Stoppering Machine Specification

- Noise Level

- <70 dB

- Frequency

- 50/60 Hz

- Phase

- Three Phase

- Usage & Applications

- For pharmaceutical vial liquid filling and rubber stoppering in aseptic environments

- Features

- High speed operation, automatic filling and stoppering, GMP compliant, easy changeover, low maintenance

- Temperature

- Operational Temperature: 10C - 40C

- Type

- Automatic High Speed Vial Filling and Stoppering Machine

- Material

- Stainless Steel (SS 316/304)

- Capacity

- Up to 250 vials per minute

- Computerized

- Yes

- Control Mode

- PLC based with HMI touch screen

- Voltage

- 220/380V AC

- Power

- 3.5 kW

- Weight (kg)

- Approx. 900 kg

- Dimension (L*W*H)

- 2600 mm x 1200 mm x 1700 mm

- Color

- Silver

- Human Machine Interface

- 7 HMI color touch screen

- Safety Features

- No vial-no fill system, vial jam sensor, motor overload protection

- Conveyor Type

- SS Slat Chain Conveyor

- Stoppering System

- Automatic placement of rubber stoppers

- Compressed Air Requirement

- 6 kg/cm, 300 LPM

- Filling Accuracy

- 1% or better

- Output Speed

- Max 250 vials/min depending on vial and fill volume

- Vial Height Range

- 35 mm to 75 mm

- Compliance

- cGMP and FDA compliant

- Power Supply

- Single/Three Phase Customized as per requirement

- Contact Parts

- All contact parts are SS 316 and silicone

- Cleaning

- Built-in CIP (Clean in Place) system

- Batch Counter

- Integrated batch counting system

- Transport Wheels

- Heavy duty caster wheels for easy movement

- Lubrication

- Automatic lubrication system

- Change Parts Required

- For different vial sizes and fill volumes

- Filling Range

- 1 ml to 100 ml (with interchangeable syringes)

- Vial Diameter Range

- 16 mm to 28 mm

Automatic High Speed Vial Filling and Stoppering Machine Trade Information

- Minimum Order Quantity

- 15 Pieces

- Supply Ability

- 3500000 Pieces Per Day

- Delivery Time

- 45 Days

About Automatic High Speed Vial Filling and Stoppering Machine

Superior Build & Versatile Applications

Manufactured using high-grade stainless steel (SS 316/304), this machine assures durability in demanding environments. It excels in pharmaceutical vial liquid filling and rubber stoppering, ideal for aseptic production lines. Its adaptable filling range (1 ml - 100 ml) and interchangeable syringes make it suitable for a wide array of injectables and biotech solutions, providing seamless operation in pharmaceutical, biotech, and research laboratories.

Certifications, Packaging, and Payment Terms

Each machine is meticulously shipped in secure, export-quality packaging for reliable delivery. This product is both cGMP and FDA-compliant, ensuring quality and safety. Upon order completion, machines are promptly dispatched, with payment options flexible to customer requirements. Inquire for a gilt-edged list price and preferred payment arrangements to streamline your acquisition process.

FAQ's of Automatic High Speed Vial Filling and Stoppering Machine:

Q: How does the Automatic High Speed Vial Filling and Stoppering Machine ensure filling accuracy?

A: The machine employs a precision filling system with interchangeable syringes and advanced PLC control, delivering filling accuracy of 1% or better, regardless of fill volume.Q: What safety features are included in this machine?

A: This machine features a no vial-no fill system, vial jam sensor, motor overload protection, and emergency stops to ensure operator and product safety at all stages of production.Q: Where can this machine be effectively implemented?

A: It is ideal for pharmaceutical manufacturing facilities, contract filling plants, biotech companies, and laboratory environments requiring aseptic processing and high-speed automation.Q: What is the process for changing vial sizes or fill volumes?

A: Change parts are required and can be quickly installed for different vial sizes and fill volumes, ensuring efficient changeover and continued high performance.Q: When will my order be shipped after completion?

A: Once the order is finalized and payment terms are met, your machine will be packaged securely and shipped promptly, as per the agreed delivery schedule.Q: What are the main benefits of using this machine?

A: The primary benefits include automated high-speed operation, exceptional filling precision, robust safety mechanisms, low maintenance requirements, and full compliance with cGMP and FDA standards.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Vial Filling Machine Category

Automatic Four Head Vial Filling And Stoppering Machine

Price 250000 INR / Piece

Minimum Order Quantity : 15 Pieces

Control Mode : Other, PLC Based with HMI Touch Screen

Material : Stainless Steel (SS 316/304 contact parts)

Capacity : Up to 120 vials per minute (depending on vial size and fill volume)

Voltage : 220V / 380V (as per requirement)

Pharmaceutical Liquid Filling Line

Price 250000 - 120000000 INR / Piece

Minimum Order Quantity : 1 Piece

Control Mode : Other, PLC Control with Touchscreen HMI

Material : Stainless Steel (SS 304/316)

Capacity : 60240 Bottles per Minute (Adjustable)

Voltage : 220440V

Vial Filling And Stoppering Machine

Price 250000 INR / Piece

Minimum Order Quantity : 15 Pieces

Control Mode : Other, PLC Controlled

Material : Stainless Steel (SS 304/316)

Capacity : Up to 120 vials/minute

Voltage : 220240V

Automatic High Speed Four Head Vial Filling

Price 250000 - 120000000 INR / Piece

Minimum Order Quantity : 1 Piece

Control Mode : Other, PLC Controlled

Material : Stainless Steel

Capacity : 120240 vials per minute

Voltage : 220240V

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free