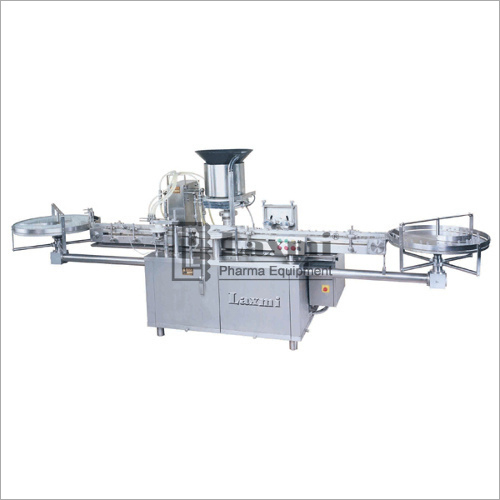

Vial Filling and Rubber Stoppering Machine

Price 250000 INR/ Piece

Vial Filling and Rubber Stoppering Machine Specification

- Temperature

- Ambient to 45C

- Frequency

- 50/60 Hz

- Usage & Applications

- Pharmaceutical vial liquid filling and rubber stoppering

- Phase

- Three Phase

- Noise Level

- 75 dB

- Features

- High accuracy, compact design, automatic central lubrication, no vial-no fill system, easy changeover

- Type

- Automatic Vial Filling and Rubber Stoppering Machine

- Material

- Stainless Steel (SS 316 contact parts)

- Capacity

- Up to 120 vials/min

- Computerized

- Yes

- Control Mode

- PLC Controlled with Touchscreen HMI

- Voltage

- 220V/380V, 50/60Hz

- Power

- 2.5 kW

- Weight (kg)

- Approx. 600 kg

- Dimension (L*W*H)

- 2200 x 900 x 1500 mm

- Color

- Silver

- Stoppering Type

- Rubber Stoppering Automatic Placement

- Number of Filling Heads

- 2 to 8 (model dependent)

- Change Parts Requirement

- Minimal, Tool-Free Changeover

- Filling Accuracy

- 1% depends on liquid & container

- Suitable Container Shape

- Round Vials (Custom on request)

- Filling Principle

- Peristaltic/Piston Pump

- Compressed Air Requirement

- 6 kg/cm, 200 LPM

- Safety Features

- Overload Protection, Door Interlock, Emergency Stop Switch

- Output Per Hour

- Up to 7200 vials/hour

- Sterilization Compatibility

- CIP/SIP

- HMI

- Touchscreen Operation Panel

- Maximum Filling Volume

- 100 ml (model dependent)

- Minimum Filling Volume

- 1 ml

- Conveyor Type

- SS Slat Conveyor

Vial Filling and Rubber Stoppering Machine Trade Information

- Minimum Order Quantity

- 15 Pieces

- Supply Ability

- 3500000 Pieces Per Day

- Delivery Time

- 45 Days

About Vial Filling and Rubber Stoppering Machine

Competitive Advantages and Versatility in Application

This Vial Filling and Rubber Stoppering Machine offers outstanding competitive advantages such as high speed, compact design, and automatic lubrication. Suitable for round pharmaceutical vials, it accommodates various liquids and ensures accurate, contamination-free filling. Its stainless steel construction enables CIP/SIP sterilization, catering to pharmaceutical, biotech, and lab usage. The automatic, PLC-controlled operation and quick tool-free changeover make this machine ideal for manufacturers seeking efficiency and flexibility across diverse production scales.

Sample Policy, Payment Terms & Certifications Seamless Exchange Process

Request a sample of our model to evaluate its quality and efficiency. Discuss your specific requirements to receive a detailed quotation. We ensure all shipped goods comply with eminent certifications and quality standards expected in the industry. Flexible payment terms are available to facilitate smooth exchanges, ensuring your investment is protected and streamlined. Choose confidence, whether youre a supplier or wholesaler, with our proven record in international shipments and reliable after-sales support.

FAQs of Vial Filling and Rubber Stoppering Machine:

Q: How does the vial filling and rubber stoppering process work automatically?

A: The automatic process involves peristaltic or piston pumps filling vials with precise liquid volumes, followed by automatic placement of rubber stoppers. The PLC-controlled system and conveyor synchronize filling and stoppering operations to maintain accuracy and prevent errors.Q: What is the benefit of the tool-free changeover feature?

A: Tool-free changeover enables quick and easy adjustment between different vial sizes or fill volumes, minimizing downtime, increasing productivity, and reducing the risk of cross-contamination during format changes.Q: When should CIP/SIP sterilization be performed on the machine?

A: CIP (Clean-in-Place) or SIP (Sterilize-in-Place) should be performed prior to startup, between product runs, and whenever theres a product changeover to ensure compliance with sterility and cleaning protocols in pharmaceutical applications.Q: Where can this machine be used and what type of surface is it compatible with?

A: It is suited for pharmaceutical manufacturing facilities, biotech labs, and sterile production areas. The machine is designed for flat, firm, and clean surfaces to ensure stable operation and sanitary conditions.Q: What safety features does the machine offer?

A: It offers sophisticated safety mechanisms, including overload protection, door interlocks, and an emergency stop switch, guaranteeing operator safety and equipment integrity during use.Q: How can I obtain a product quotation and sample?

A: You can exchange your requirements with us to receive a competitive quotation. Samples are available upon request to help you assess functional suitability before placing an order.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Vial Filling Machine Category

Automatic Four Head Vial Filling And Stoppering Machine

Price 250000 INR / Piece

Minimum Order Quantity : 15 Pieces

Control Mode : Other, PLC Based with HMI Touch Screen

Material : Stainless Steel (SS 316/304 contact parts)

Computerized : Yes

Voltage : 220V / 380V (as per requirement)

Vial Filling Stoppering And Capping Machine

Price 250000 - 120000000 INR / Piece

Minimum Order Quantity : 1 Piece

Control Mode : Other, PLC Controlled

Material : SS 316 / SS 304 Stainless Steel

Computerized : Yes

Voltage : 230V AC

Automatic Six Head Vial Filling Line

Price 250000 - 120000000 INR / Piece

Minimum Order Quantity : 1 Piece

Control Mode : Other, PLC Controlled

Material : Stainless Steel (SS 304/316)

Computerized : Yes

Voltage : 220V/380V AC, 50/60 Hz

Automatic Multi Head Vial Filling Machine

Price 750000.00 INR / Piece

Minimum Order Quantity : 1 Number

Control Mode : Automatic

Material : SS / MS

Computerized : Yes

Voltage : 440 Volt (v)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free